The tunic, the ancestor of the shirt

The oldest preserved shirt dates back to Antiquity (around 3000 BC). At that time, we did not speak of a shirt but rather of tunic . It consisted of two sleeves and a side seam. The tunic was generally made of linen, wool, or silk.

Linen tunic dating from the end of the 11th Egyptian dynasty (-2033 - -1862)

Later, in the 5th century, the tunic was not meant to be seen; it became the camisia. It was not meant to be elegant, as it had no precise shape or dimensions. However, it was meant to protect the skin from the rougher clothing that was worn at the time. The camisia therefore served as underwear.

Later, the Persian tunic was brought back to Europe by the Crusaders. The tunic consisted of sleeves that were cut and then sewn at the wrists. They no longer went down like the previous tunics but were worn short by men. This began the transformation of the tunic into the shirt.

A use that evolves over the years

A pair of underwear

In the Middle Ages, the shirt did not yet have that very clean and refined appearance as we see it today. Shirts were made of linen or wool, very durable raw materials. Thus, they could be washed and boiled regularly, the issue of hygiene being important in the 13th and 14th centuries.

It was during this period that semi-buttoned shirts appeared: they were buttoned only above the chest, and bore a symbol: the longer the shirt, the wealthier its owner.

A sign of social distinction

In the 15th century, the shirt, which had previously been little more than an undergarment, became fashionable and had to be visible. Noble materials like silk took precedence over coarser materials like wool and linen. The shirt became more refined, and a collar was added.

The whiteness of the shirt is emphasized by the open neckline. The shirt now becomes a sign of social distinction.

In the following century, the style of the collar and cuffs of shirts became heavier with lace, embroidery and buttons. Social status is reflected in the decoration of the shirt.

A segmentation between men and women

Gradually buttonholes develop and with them the difference between feminine and masculine articles. Thus, the buttonhole is on the right for men, while it is on the left for women. In the 17th century, high-ranking women were dressed by maids and the buttonhole being on the left made their work easier.

In the 18th century, men wore shirts with lace cuffs and a white jabot. When Napoleon came to power in the early 19th century, the shirt was hidden, revealing only the cuffs and collar. It also became longer, and the collar was raised to a point, held in place by a tie.

A sector in constant motion

The emergence of the tailor's trade, the shirt as an element of distinction

It's at The tailoring service appeared in the 17th century . Shirts were then cut and sewn by hand. The tailor incorporated luxurious elements and the now made-to-measure shirt is a guarantee of good taste and success.

Hannah Montague, an American woman living in New York in 1820, would take the collars off her husband's shirts and wash them separately. This way, her husband always gave the impression of wear a clean shirt . From this idea, Mrs. Montague filed a patent in 1927 and started a business manufacturing removable collars . Success quickly came and the business grew.

Competing companies opened, and soon removable cuffs appeared in turn. At the beginning of the 20th century, the manufacture of collars and cuffs and the associated laundry were a separate industry. The products of this industry were primarily intended for the wealthy classes. White-collar workers were distinguished from blue-collar workers.

The creation of standard sizes, towards mass production

In 1850, through a patent, the firm of Brown, Davis & Co of Aldermanbury invented a mass-produced shirt. At the beginning of the 19th century, clothing, and especially shirts, was made by tailors and seamstresses scattered across the country. The Industrial Revolution brought these skilled workers together in specialized workshops.

The design, cutting and ironing of the shirt are grouped together and carried out within a single unit, the sewing remains separate and is subcontracted by other companies. Thanks to these new organizations, manufacturing capacities increase And clothing is gradually becoming more democratic.

At the beginning of the 20th century, the First World War marked a turning point. To quickly and economically clothe its soldiers, the American army developed a system of standard clothing sizes. This rationalization allowed for increased production and lower costs; companies adopting these methods were called " confectionery ."

The industrialization of the sector

Between the two wars, Americans, fond of Parisian fashion, imported French clothing on a massive scale. The Second World War suspended trade between the United States and Europe, and more specifically, the North American supply of Parisian couture.

The United States then had to produce work clothes and uniforms on a massive scale themselves. Industrialization combined with the standardization of sizes allowed them to no longer depend on Paris, and soon, clothing manufacturers decided to make simpler clothes , cheaper , including Production is faster . This method, called “ Ready to wear ”, will considerably influence French fashion after the war.

Easy access to work equipment

As soon as hostilities ended, Albert Lempereur, president of the Federation of the Women's Clothing Industry, made the French press and manufacturers aware of American methods.

Little by little, the principles of “Ready to Wear” are becoming established in France. The Parisian company Weill democratizes the notion of “Clothing that fits” and Introduces the concept of ready-to-wear in France . Ready-to-wear soon covers all types of clothing. It gradually refers to the concept of mass-produced clothing, with a size system and bearing a brand label.

We quickly found designer ready-to-wear, designer ready-to-wear, and ready-to-wear for workers. All phases of garment design were grouped together in production units. Quality clothing inspired by fashion thus became more accessible.

The beginnings of lasting clothing

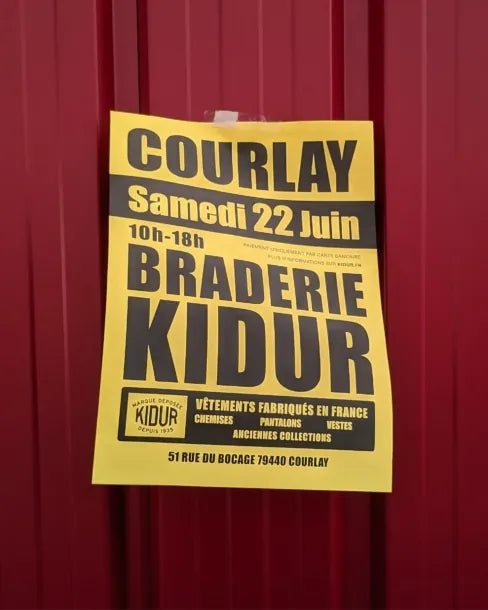

Since 1927, the Kidur factory has been producing high-quality, strong, and wear-resistant fabrics in France. Initially known for their fabrics that last , the founders Juste Lucain Husseau and René Moynaton registered the Kidur trademark in 1935 .

Kidur was a time when fabrics were intended for the working world, for the manufacture of workers' clothing, thick and robust fabrics that did not fade, twills and moleskins made in France. Workers needed inexpensive but durable and good quality clothing to work. To improve their working conditions, the clothing also had to protect them from the dangers of machinery and from dirt.

The shirt, an essential worker's garment

Workwear also needed to be protective, comfortable, functional, and suited to different environments. Since 1945, thanks to the creation of a clothing company combined with the Plainelière weaving mills, the Kidur factory has been using its expertise and robust, durable fabrics to provide factory and field workers with quality clothing.

Initially Kidur will be known for his shirts , then for a complete wardrobe of durable clothing . The quality of manufacture, the strength of the fabrics and the great color fastness give Kidur clothing exemplary durability. From the very beginning of the brand, Kidur has ensured its commitment with the slogan “Kidur, resists wear and tear”

From work clothes to everyday clothes

an ambition that lasts

For more than half a century, the Kidur factory dressed workers in factories across the country, and its quality and expertise were recognized by all. Kidur was the benchmark for clothing that resists wear and tear .

Later, like so many others, the factory was surprised by the arrival on the market of disposable clothes from the other side of the world. Unable to compete, the factory refocused on what it did best: manufacturing, but this time for others.

She left her historical mark, this little piece of heritage sleeping at the bottom of a cupboard while waiting for the notion of consuming sustainably, responsibly and locally is once again becoming a choice criterion .

In 2018, feeling the wind change, she restarted the machine. Kidur has had a makeover with a timeless collection in keeping with its origins, a broader collection of timeless clothing, still as solid, and still made in Courlay, France, in the historic factory .